© 2012 : Privacy Policy

Av. Jose Alcalde Delano 10581, of 501, Lo Barnechea, Región Metropolitana. Phone: +56 2 32 03 9516 E-mail: contacto@minetrust.com

© 2012 : Privacy Policy

Av. Jose Alcalde Delano 10581, of 501, Lo Barnechea, Región Metropolitana. Phone: +56 2 32 03 9516 E-mail: contacto@minetrust.com

Contacto

Póngase en contacto con nosotros y le ayudaremos a encontrar una solúcion óptima para el desafío que tenga.

+562 32 03 9516

contacto@minetrust.com

FINDRAW

Services of alignment of conveyor belts , using innovative equipment of last generation in order to increase the production of transported material, improving the useful life of the belt.

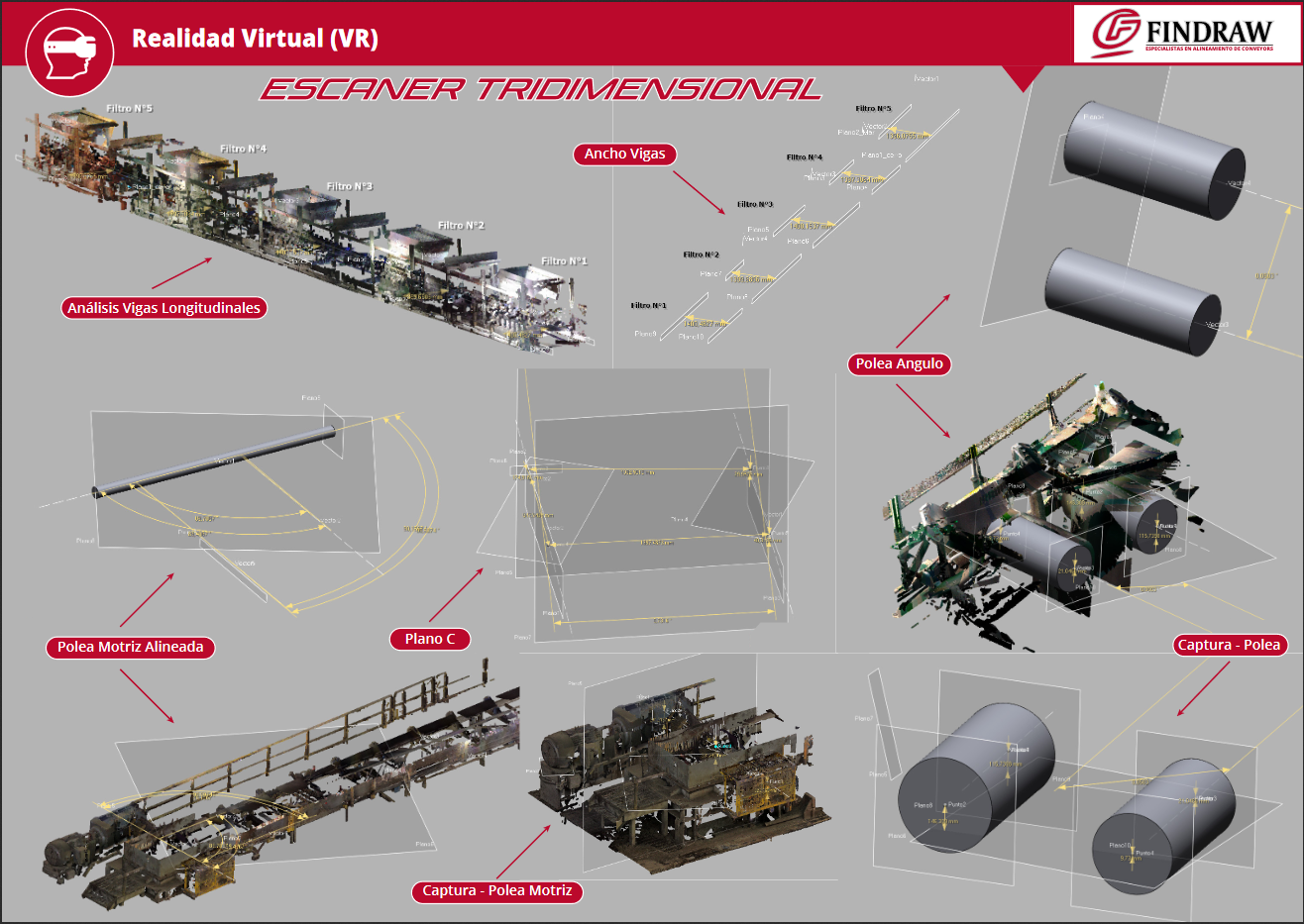

Immersive Inspections - VR

We believe in new technologies and we bet on new experiences that allow us to improve, implement and innovate diverse areas through these immersive tools, reducing costs, optimizing information and allowing focus to improve content.

Alignment of System Conveyors

Our work methodology is based on a 4-stage solution plan .

1. Ground Survey

The current status of your conveyor system is documented and a survey of the current condition on the ground is made

2. Documented Technical Advice.

Through a technical report we show the causes of misalignment and propose the solution.

3. Staff Training.

We provide field assistance to ensure that corrections are made correctly. Previously, the personnel involved in the maintenance are trained.

4. Monitoring and Evaluation.

Inspection visits are carried out periodically to record the performance of the installed equipment and verify its treatability.

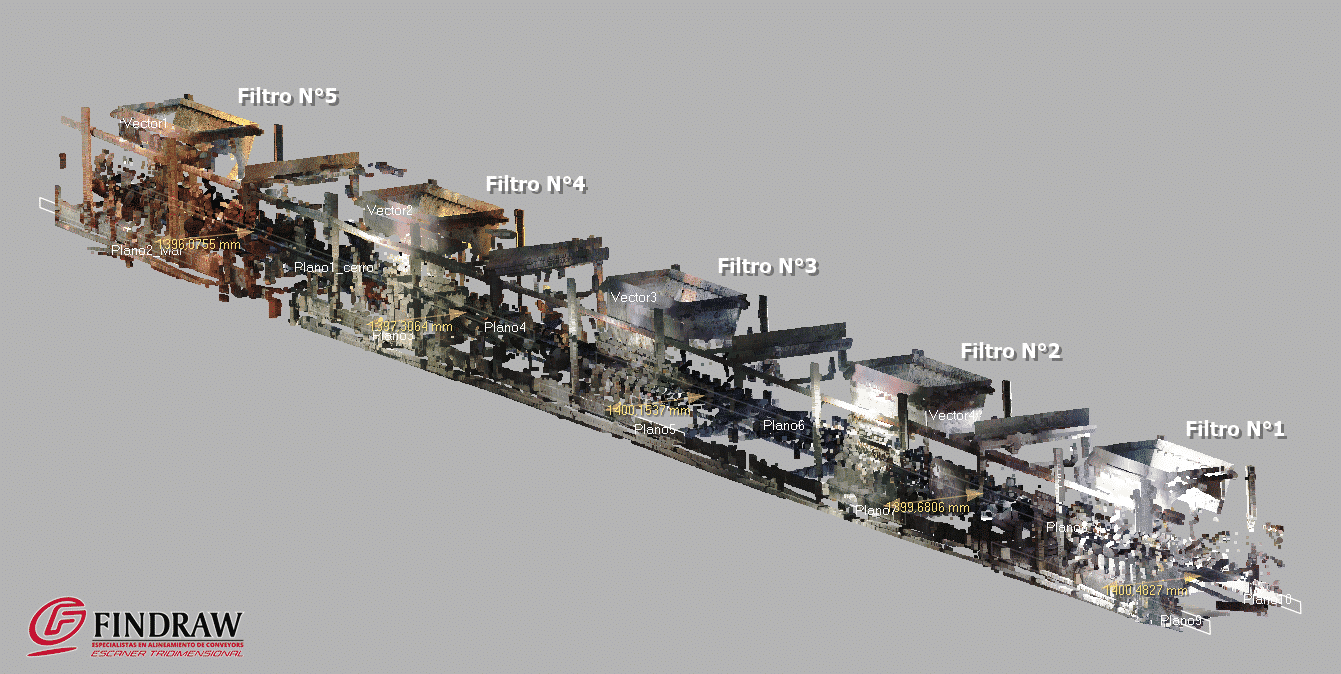

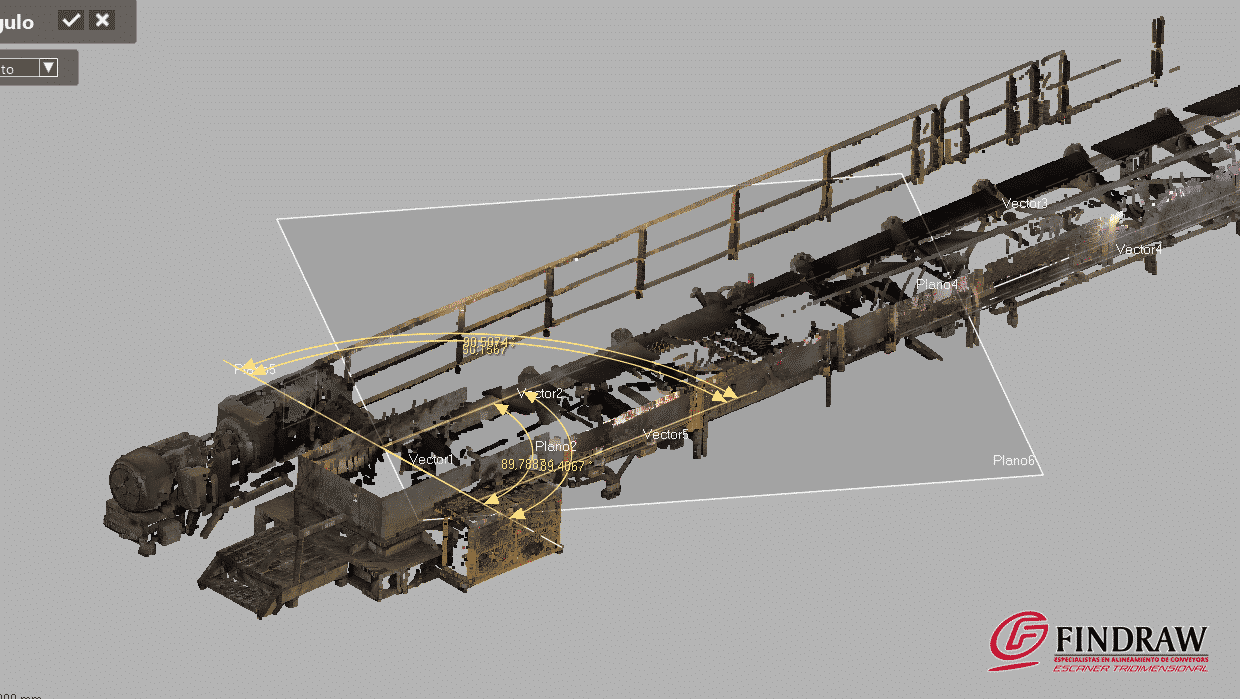

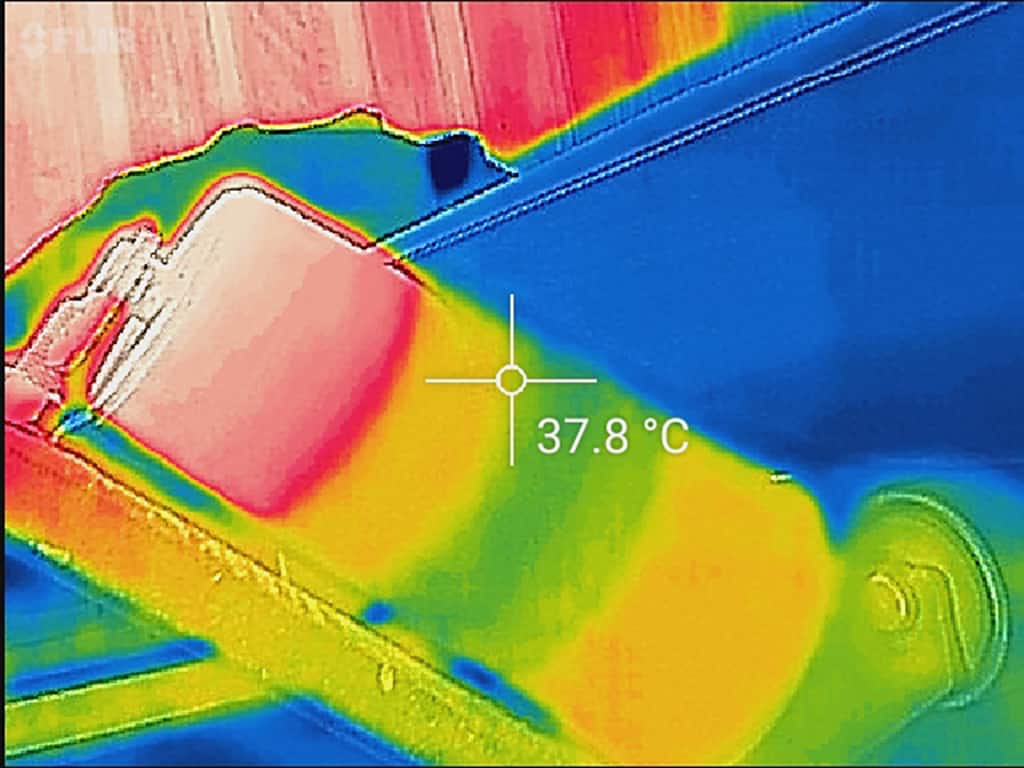

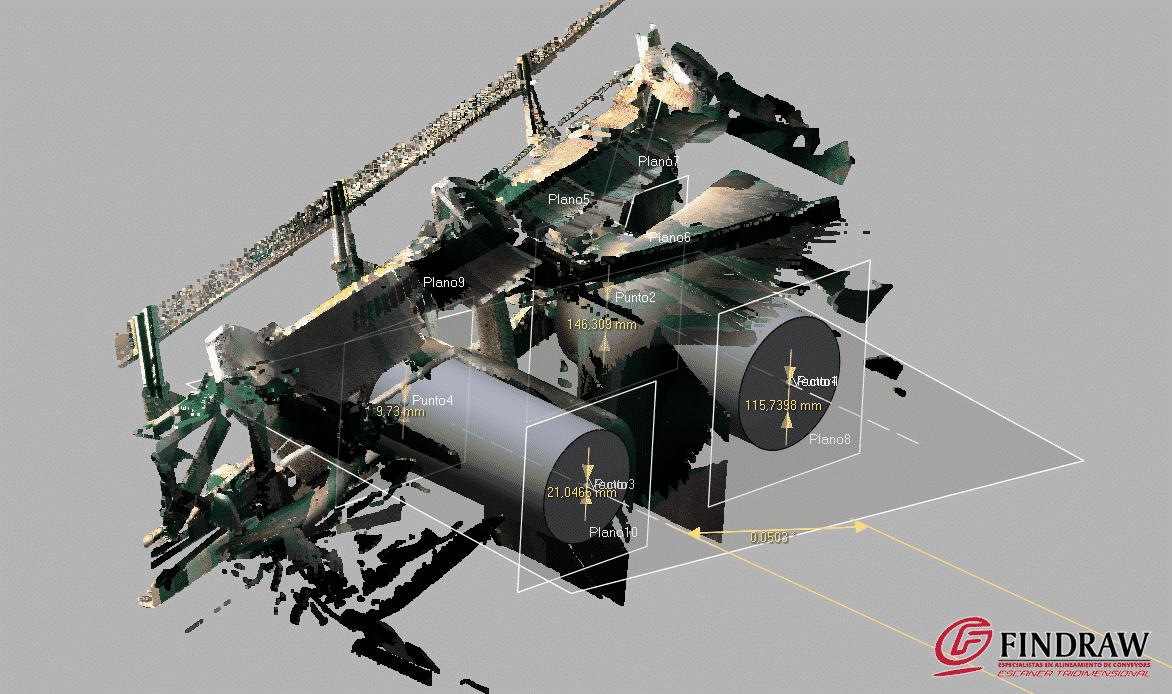

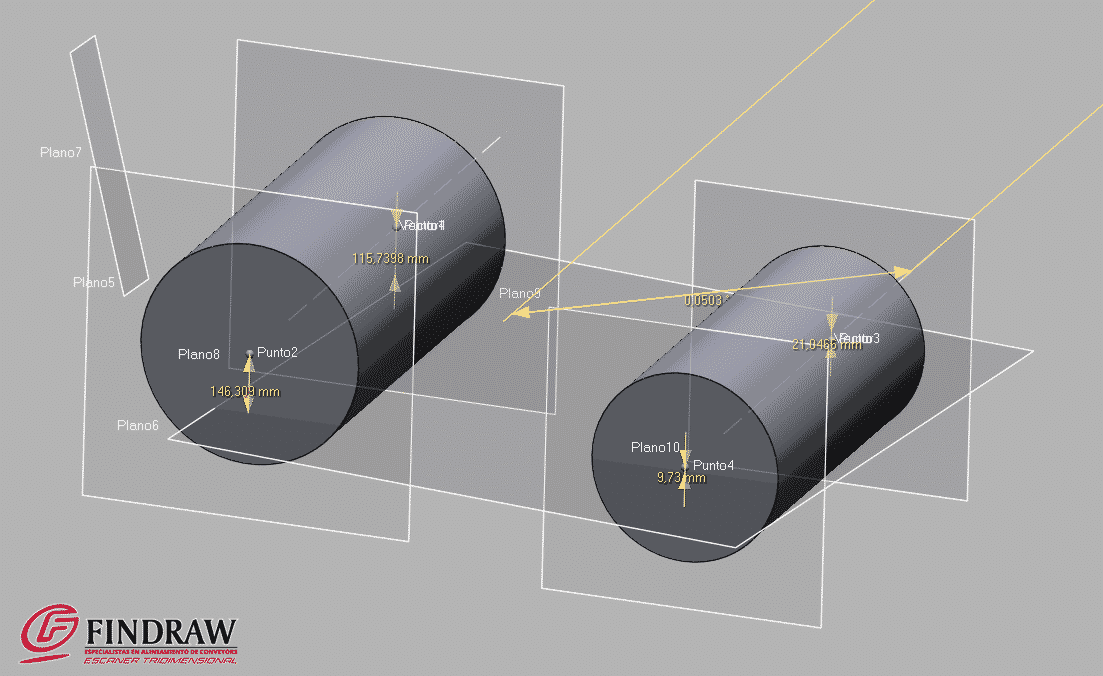

Three-dimensional Laser Scanner

At Findraw we are always incorporating the latest technology into our processes in order to deliver reliable solutions in the shortest time. For decision making, it is vital to have accurate and up-to-date information on the equipment in operation in order to reduce the risks associated with the work and the optimization of the processes and their spare parts together with all the elements that make it up.

Productive, safe and reliable results for the global material transport industry.

• 3D Structural Survey in the Field.

• Data processing: Point Cloud.

• Structural Analysis of: beams, pulleys, stations and rollers, etc.

• Analysis of equipment wear.

• 3D modeling.

• Preparation of 2D plans, As-Built.

• Technical Reports with 3D Backup.

This type of high-precision three-dimensional analysis will allow you to:

1. Increase the availability of your conveyor equipment.

2. Increase the material transport capacity.

3. Longer life of the conveyor belt.

4. Energy saving.

5. Availability of updated dimensional information of the components, pulleys, skids, chutes, plates, protections, etc.

6. Identify the cause of the misalignment.

Contraseña de Usuario Mine Trust:

Contraseña Incorrecta.