© 2012 : Privacy Policy

Av. Jose Alcalde Delano 10581, of 501, Lo Barnechea, Región Metropolitana. Phone: +56 2 32 03 9516 E-mail: contacto@minetrust.com

© 2012 : Privacy Policy

Av. Jose Alcalde Delano 10581, of 501, Lo Barnechea, Región Metropolitana. Phone: +56 2 32 03 9516 E-mail: contacto@minetrust.com

PULLEYS

MINE TRUST, through its represented German for pulleys, world leaders in the manufacture and development of pulleys of high efficiency and durability under DIN standards, has the full range of pulleys necessary for the conveyor system, such as: Motors, Tail , Tensioners, Conductors, Deflectors, etc., ensuring that your customers will receive the best quality available in the market at a price commensurate with the current economic situation.

MANUFACTURING RANGES:

√ Pulleys with diameters up to 2,500 mm

√ Pulleys with lengths up to 6,000 mm

√ Drums for loads greater than 4,000 kN

All kinds of pulleys for conveyor belts are designed and manufactured.

The design and calculation are made individually according to the requirements and particular conditions of each client.

Manufacturing is carried out under strict control parameters, counting with suppliers of raw materials of the highest quality standards worldwide.

BEARINGS AND BEARINGS

SKF, FAG or LFD (all of German origin)

Spherical bearings are designed and manufactured to the lowest tolerances available on the market to ensure the highest possible life.

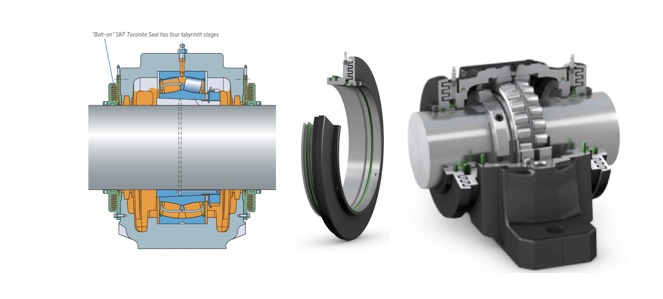

SPECIAL SKF TACONITE SEAL SYSTEM (ALTERNATIVE)

Labyrinth seal "Taconite" patented by SKF available for bearings, which guarantees the highest resistance against water and dust.

Some features of SKF's Taconite heavy-duty seal are:

➢ Cartdrige Taconite iron or machined cast steel

➢ Labyrinth of 3 or 4 stages

➢ Internal V-ring to avoid contaminants

➢ Labyrinth type rotary ring faces the bearing to divert and eject water.

➢ Installed in a reduced axial length.

➢ The labyrinth-type rotary ring is sealed to the shaft by an O-ring.

➢ ± 0.5 ° of misalignment capacity

CUERPO DE POLEA

Turbine shell and covers manufactured in material S355J2 and tested by ultrasound under DIN EN 10160

Certification of APZ 3.1 material according to DIN EN 10204

The flange is welded to the tube by means of welding with powder ("Powder Welding Method") which guarantees a greater penetration of the welding and ensures that said welding will not suffer damages during the whole life of the pulley.

This method is the best currently used in highly dynamic applications such as boats and pulleys.

The welding is tested / approved by ultrasound.

The mantle is then subjected to low stresses to avoid any risk of crack growth.

This process is carried out on all types of material that is subject to high dynamic use as pulleys are.

AXLE OF THE PULLEY

Material of shaft 42CrMo4 with APZ 3.1 certification according to DIN EN 10204

Material tested by ultrasound according to DIN EN 10228-3

Shaft designed and calculated under DIN 54130

Mechanized bearings correspond to IT 6

FIXING SYSTEMS

The shaft is assembled to the tube by means of original BIKON fixing systems. (Alternatives according to requirement)

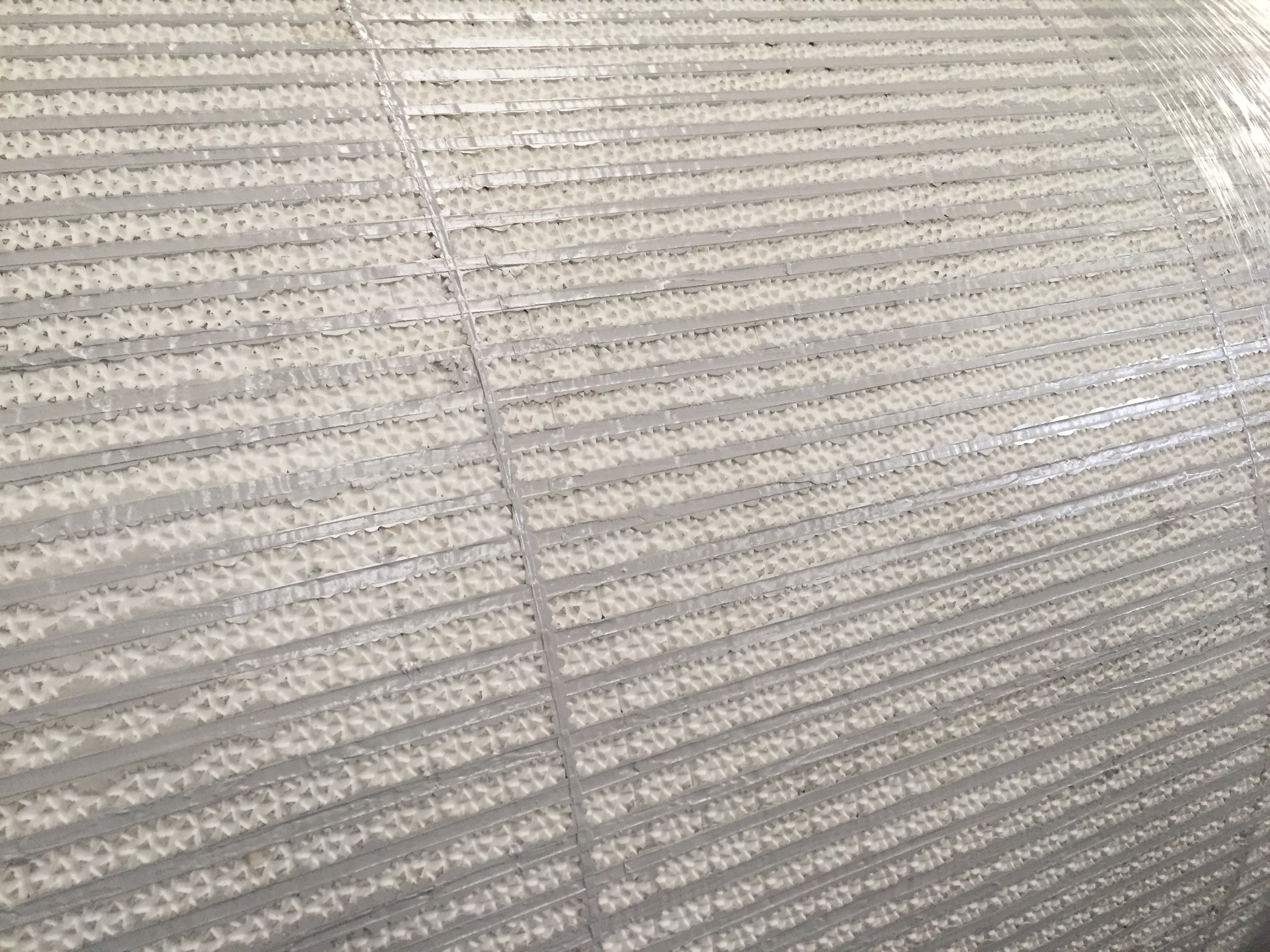

COATING

Rubber vulcanized in hot, diamond for motor pulleys (86x50) and smooth for return pulleys.

Thickness of 25 mm and hardness of 65 ° Shore A for driving pulleys and 20 mm for the return.

Abrasion index less than 80 mm³ (in compliance with ISO 4649)

Ceramic-Ceramic and Ceramic-Ceramic for higher voltage applications

It is analyzed case by case according to customer requirements and / or operation

BALANCE

All pulleys are statically balanced in compliance with ISO 1940, class G40.

PAINTING

Bearings and metal parts of the pulley, like the flanges, have 2 layers of paint.

First a base of 80 μm of paint and an additional second of 80 μm RAL 5015

ASSEMBLY

All the pulleys are assembled ready to use.

The axles are mounted to the pulley body by BIKON elements and are screwed with a torque wrench to ensure that the tightening torque is correct.

Only this and the experience of the highly qualified workers who have the knowledge of how to do it, guarantees an efficient assembly and without deformations.

The deformation in the assembly is the highest risk to reduce the life time of the entire pulley, due to the tension force that is exerted on the bearing / bearing.

Bearings are mounted on the shaft and greased for use.

Contraseña de Usuario Mine Trust:

Contraseña Incorrecta.