© 2012 : Privacy Policy

Av. Jose Alcalde Delano 10581, of 501, Lo Barnechea, Región Metropolitana. Phone: +56 2 32 03 9516 E-mail: contacto@minetrust.com

© 2012 : Privacy Policy

Av. Jose Alcalde Delano 10581, of 501, Lo Barnechea, Región Metropolitana. Phone: +56 2 32 03 9516 E-mail: contacto@minetrust.com

BENEFITS OF DOING OVERHAUL

Generate solutions so that customers can achieve the planned availability of their process, that is, maintain their production levels, by:

1. Inefficient cost reduction

• Unforeseen detentions

• Quick replacement of the spare part

2. Decrease in the preventive cost.

• Planned arrests

• Planned replacement of the spare

Increase production levels, with solutions through:

1. Increase of the useful life of the pulleys achieving a smaller amount of changes.

• Decrease in the frequency of maintenance, which implies an increase in production.

2. Improvements in the designs according to increase the tonnage processed.

DESCRIPTION OF THE MATRIX OF SOLUTIONS

The Pulley Overhaul technical proposal consists of the following services:

• to. Inspection of coating thicknesses and mantle

• b. Removal of coating and Rectification of Mantle

• c. Shaft and sleeve change

• d. Application of coating and breaks

to. Inspection of coating thicknesses and mantle

b. Removal of coating and Rectification of Mantle

c. Shaft and Sleeve Replacement

d. Assembly breaks

DESCRIPTION OF THE MINE TRUST COMPARATIVE ADVANTAGE.

Minera's Pulley Overhaul service has been designed to deliver tailor-made solutions as the primary source of asset protection for your plant.

• Reengineering:

The pulley overhaul unit of Mine Trust, seeks the recovery of components with wear problems to achieve improvements in performance and reduction in 4 directions.

1. REDUCTION OF THE COST OF FAILURE

2. REDUCTION OF INVENTORY COST

3. REDUCTION OF INTERVENTION COSTS.

4. REDUCTION OF OPERATING COSTS

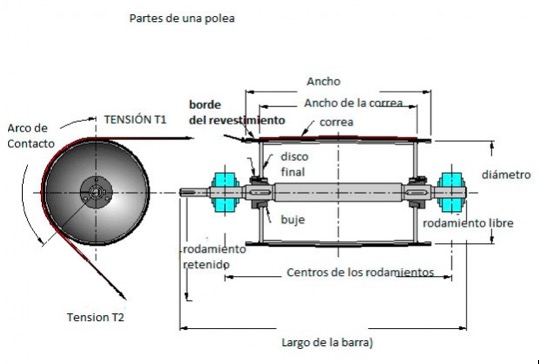

Pulleys are a key part of the process of transporting minerals through conveyor belts. They have the function of generating the mobility of the mineral through the belts. Like all mechanical equipment, they are subjected to stress, deformation and wear of their components. Depending on the dimensions of the pulleys or their installation, it is difficult to transfer them to be able to perform the overhaul service or maintenance in workshops. Therefore, this process is usually carried out in the field or simply a pulley change is made. The most common practice is that the old pulley is not reconditioned and transformed into waste or scrap. This is unfriendly to the environment and the opportunity to salvage parts in good condition that can be reused to build a new pulley is wasted. If, on the contrary, the pulley is subjected to an overhaul, the mining company receives a certificate stamped by Gerdau. This certifies that the pulley in poor condition was discharged and thus can be deleted as active. The parts in good condition will be rescued from the equipment and reused for the manufacture of a new pulley, with the ensuing cost savings that this will imply.

PULLEYS OVERHAUL

Contraseña de Usuario Mine Trust:

Contraseña Incorrecta.